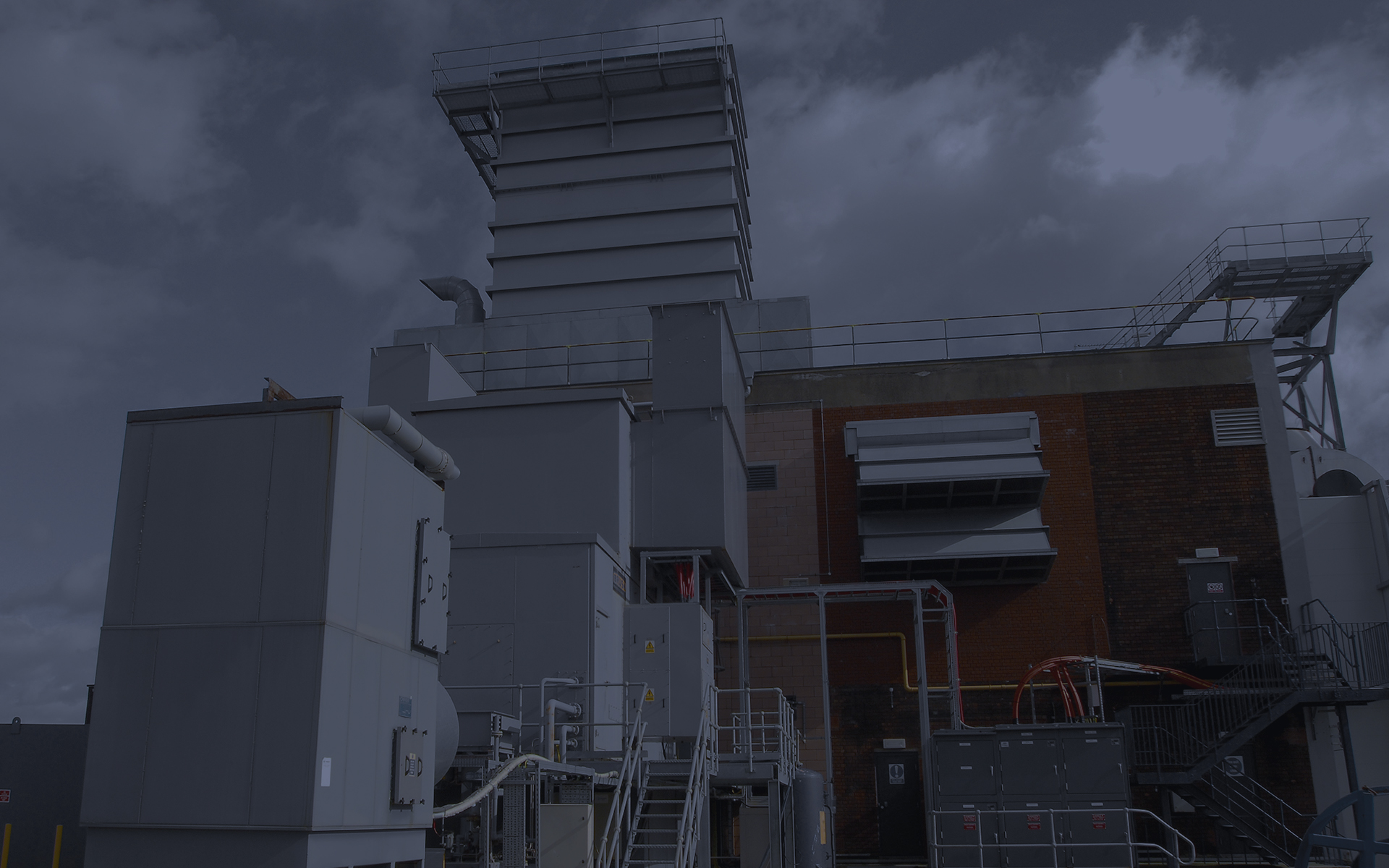

Industrial and marine gas turbine engines typically require a radial or axial exhaust collector/diffuser to redirect exhaust gases while minimizing back pressure. We have field tested our Exhaust Collector and Diffuser (C/D) designs for the GE LM2500/LM6000 series of industrial gas turbines and the Rolls-Royce Trent Marine and Industrial gas turbines in demanding test facilities and industrial applications in both North America and Europe.

Exhaust Collector & Diffusers

When used as an ejector, the silencer/exhaust tube and C/D set act together to form an ejector pump. As high velocity air is ejected from the C/D into the silencer/exhaust tube, test cell air is entrained into the stream and ejected from the test cell along with the exhaust gases, ensuring there is a steady flow of air through the test cell when the engine is in operation.

Features

- Available hard-ducted or for use with an ejector system

- Made from welded stainless steel assemblies and available in various sizes

- Proven reliability in applications with excessive thermal cycling

- Available with standard straight discharge or angled discharge, depending on engine type and test cell configurations

- Diffuser profiles are spun to tight dimensional specifications for radial diffuser configurations

- Engine exhaust interface can be customer defined or consist of a proven MDS piston seal arrangement

- Mounting configurations can accommodate the thermal growth of an engine

- Wrapped in flexible removable insulation blankets and covered in fiberglass fabric to reduce heat emissions into the test cell, provide personnel safety, and reduce thermal cycling of the collector / diffuser

- The MDS C/D design can be adapted to any engine size or type