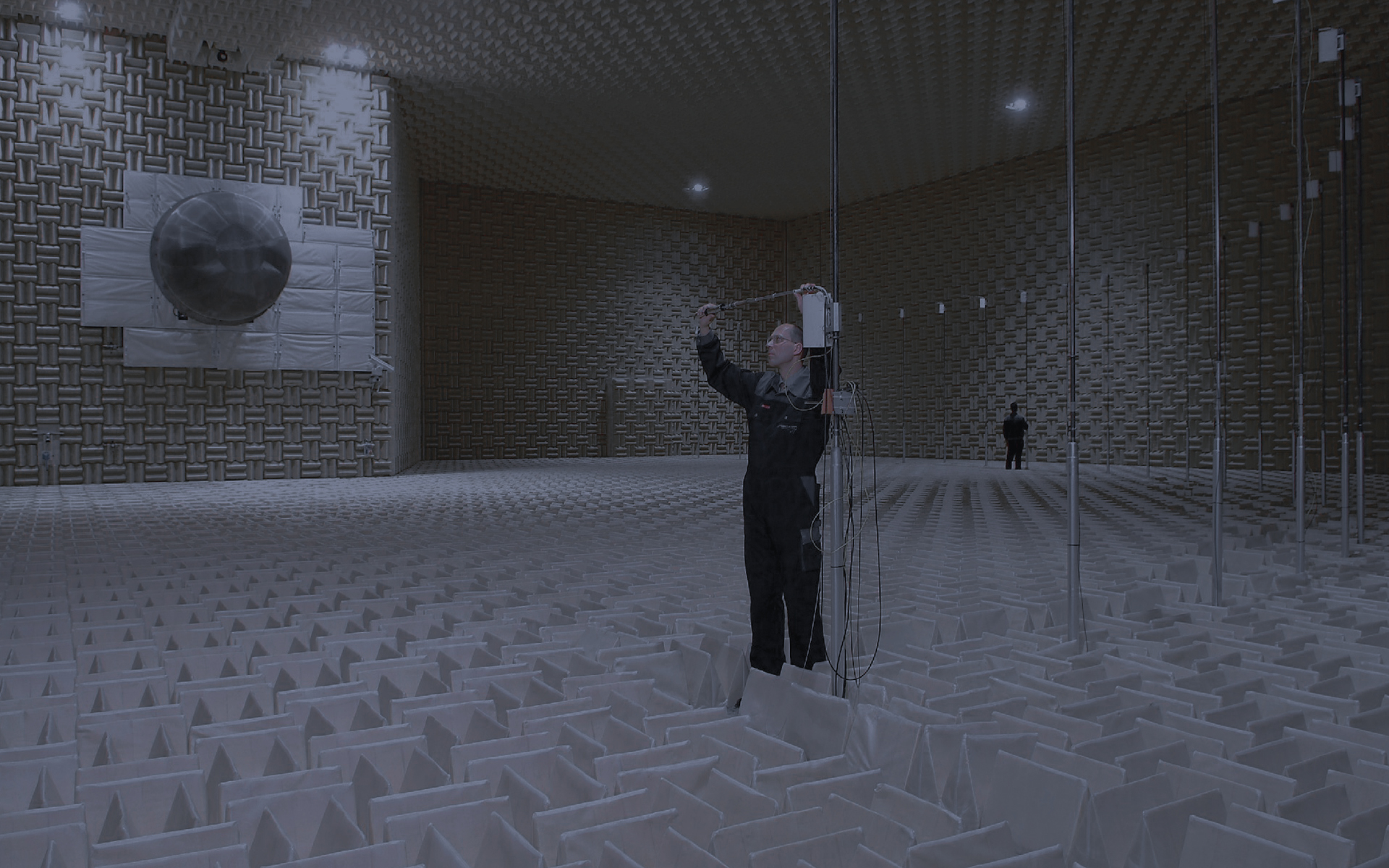

With our sophisticated software and scale modeling techniques for both aerodynamic and acoustic modeling, we can ensure that our cost-effective aeroacoustic products work right the first time. Our ongoing commitment to research and development gives you access to the foremost technologies and practices in this field.

AeroAcoustics Products

We have a comprehensive understanding of test cell aerodynamics and acoustics and their complex interaction. Creating a representative aerodynamic environment requires a carefully engineered layout and the use of suitable aerodynamic flow conditioning devices. Proper aerodynamics not only prevents engine operational problems, but also minimizes harmful low frequency noise (infrasound) which is difficult to attenuate and prohibitively costly to rectify.

We carry out a detailed analysis of flow and acoustic conditions to meet the conditions of the most demanding engine test requirements. MDS’s designs ensure that the airflow is of such quality that it prevents vortex generation and ingestion by the engine, as well as recirculation of exhaust gases within the test cell.

Intake system products include the following components:

- Silencers – Designed to attenuate noise produced by the engine while providing uniform, low turbulence airflow with minimum pressure loss to the engine.

- Flow Screen – Uniform flow conditions are crucial when testing a gas turbine engine and a flow screen plays an important role in ensuring these ideal conditions. We install the flow screen across the entire cross section of the test cell downstream of the intake stack, and we designed the open area of the flow screen to provide the optimum pressure drop conditions in a test cell.

- Turning Vanes – Designed to assist in redirecting the inlet air flow from a vertical flow to a horizontal flow uniformly.

- Cross Wind Straighteners – Fabricated from corrosion resistant material and secured to the upper surface of the intake stack. MDS’s cross wind straightener is made up of a series of flow grid plates designed to mitigate the effects of crosswinds on the aerodynamic performance of the test cell.

Exhaust system products include the following components:

- Augmentor Tubes – These serve two purposes, to cool the exhaust gases by mixing them with fresh air and to attenuate noise. MDS’s research confirms a direct correlation between the dimensions of the augmenter tube and the amplification of test cell infrasound.

- Exhaust Basket – Enhances audible noise reduction by shifting the exhaust noise low frequencies to higher and better managed frequencies. The exhaust basket termination, perforation pattern, and the effective open area impact the generation and amplification of infrasound.

- Exhaust Silencers – Designed to meet noise requirements without imparting excessive cell depression and exhaust backpressure.

- Access Doors – Acoustically treated and designed to withstand the operational and air depression / fluctuations and brief explosive over pressures typically specified by regulations.