The nxDAS Suite of Software

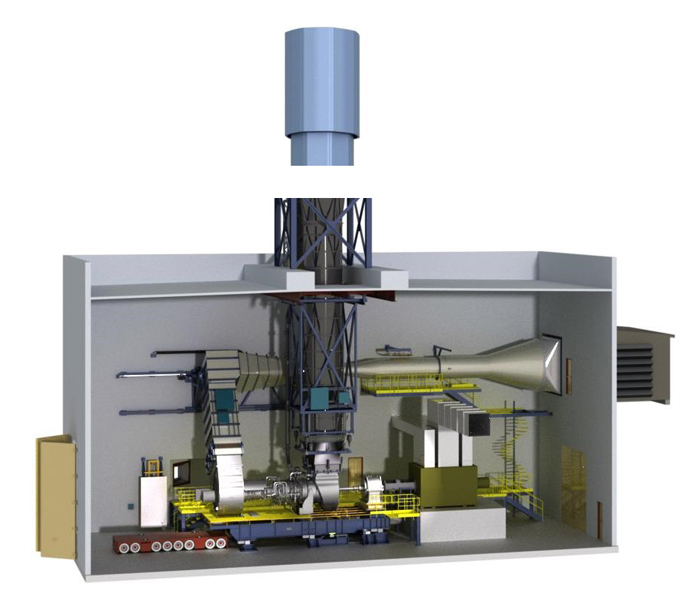

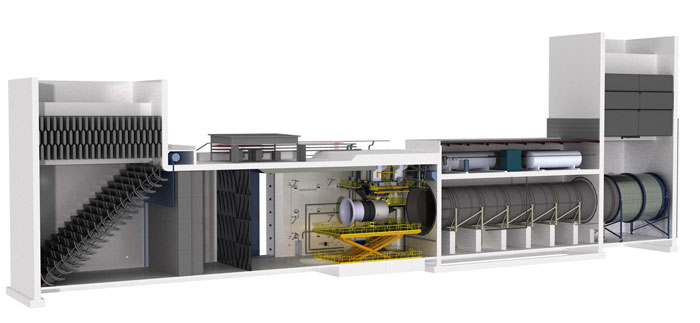

Scalable. Flexible. Modular. Built for the Future of Testing. For 40 years, MDS has been developing advanced data acquisition systems (DAS) for customers around the world. Servicing a variety of clients in the engine testing industry, our solutions are unique and built to meet the......