About Us

Now, what does that really mean?

Whether taking you on vacation, shipping cargo across the ocean, or at the end of a 1,000 km gas pipeline, gas turbine engines must be reliable and safe.

We provide our clients with the capability to HARNESS THE POWER of these engines and test them in an environment that mimics their real-world application.

We have the capability to turn an empty piece of land into a functioning, state-of-the-art test facility in less than two years; this includes all engineering and design, construction management, and project management.

We drive the industry forward.

Gas turbine engines are used in marine and aviation propulsion and also have applications in industrial power generation. Since 1985, MDS has been trusted to design and build test facilities for engine manufacturers all over the world.

Making our industry

smarter, greener, and more powerful.

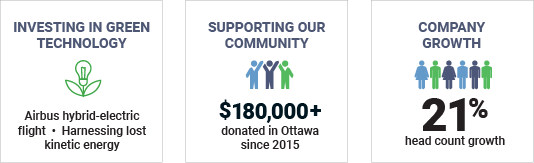

We are always laser-focused on making our industry smarter, greener, and more powerful. Through our partnerships, such as our leadership of the NRC Aerospace Research Advisory Board, we are able to be a part of our industry’s future in a meaningful way.

From building the world’s most advanced, one-of-a-kind gas turbine engine test facilities—with projects in more than 20 countries—to being at the forefront of research and development, MDS continually drives innovation. Its engineering division works with national governments and universities to innovate and spearhead the industry in new and leading-edge testing technologies.

MDS simply would not be in business if innovation took a back seat.

We focus on making a long-term impact on our industry worldwide including our patented green technology that could change the face of engine testing.

The world’s biggest engine manufacturers trust MDS.

The major players in the engine manufacturing business, like Solar Turbines, Pratt & Whitney, and Rolls-Royce, have been working with MDS for decades and have contracted well over half a billion dollars’ worth of work with us. Household names like Siemens and Air France have also been long-time customers of MDS.

We collaborate with the best professionals in our field.

- Airbus

- Rolls-Royce

- Air France

- MAN Energy Solutions

- Pratt & Whitney

- Siemens

- Solar Turbines

We deliver the most reliable and environmentally responsible solutions.

Our employees are proud to work for an industry leader, always pushing our industry forward, and pushing the boundaries of what’s possible.

Quality Assurance

MDS is proud to meet or exceed the following national and international standards:

- AS9100 Registered (MDS AeroTest)

- ISO 17025 Registered (MDS Europe)