MDS relies on 30 years of experience in the aviation, industrial, and marine industries to design and supply of one-of-a kind specialist component test facilities.

Engine Component Test Facilities

Our component test facilities for key engine components (such as: fan, core engine, compressor, combustor, and turbine) are driven by the same passion for excellence as our full engine test facilities.

We have built a team of in-house experts who help us plan and deliver complex component facilities with unparalleled agility. Let our exceptional track record and experience in this space work to your advantage—share your challenges with us and we’ll demonstrate how you can achieve a competitive advantage in this highly specialized field.

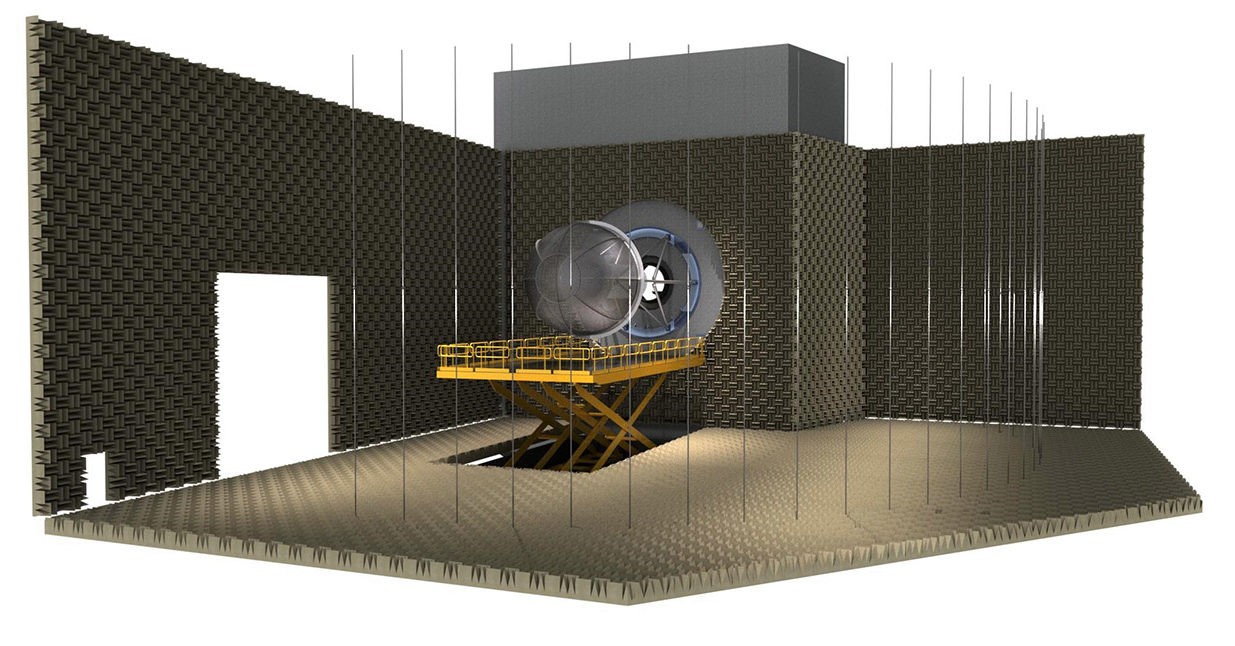

Fan Test Facility (Anechoic Chamber)

Fan test facilities have been designed and supplied by MDS to test aerodynamic performance and noise characteristics of development fan test rigs. MDS designs fan test facilities with low acoustic signatures of test system components, and turbulence control screen (TCS) devices to emulate the engine and acoustic signature of the fan test articles in a free field.

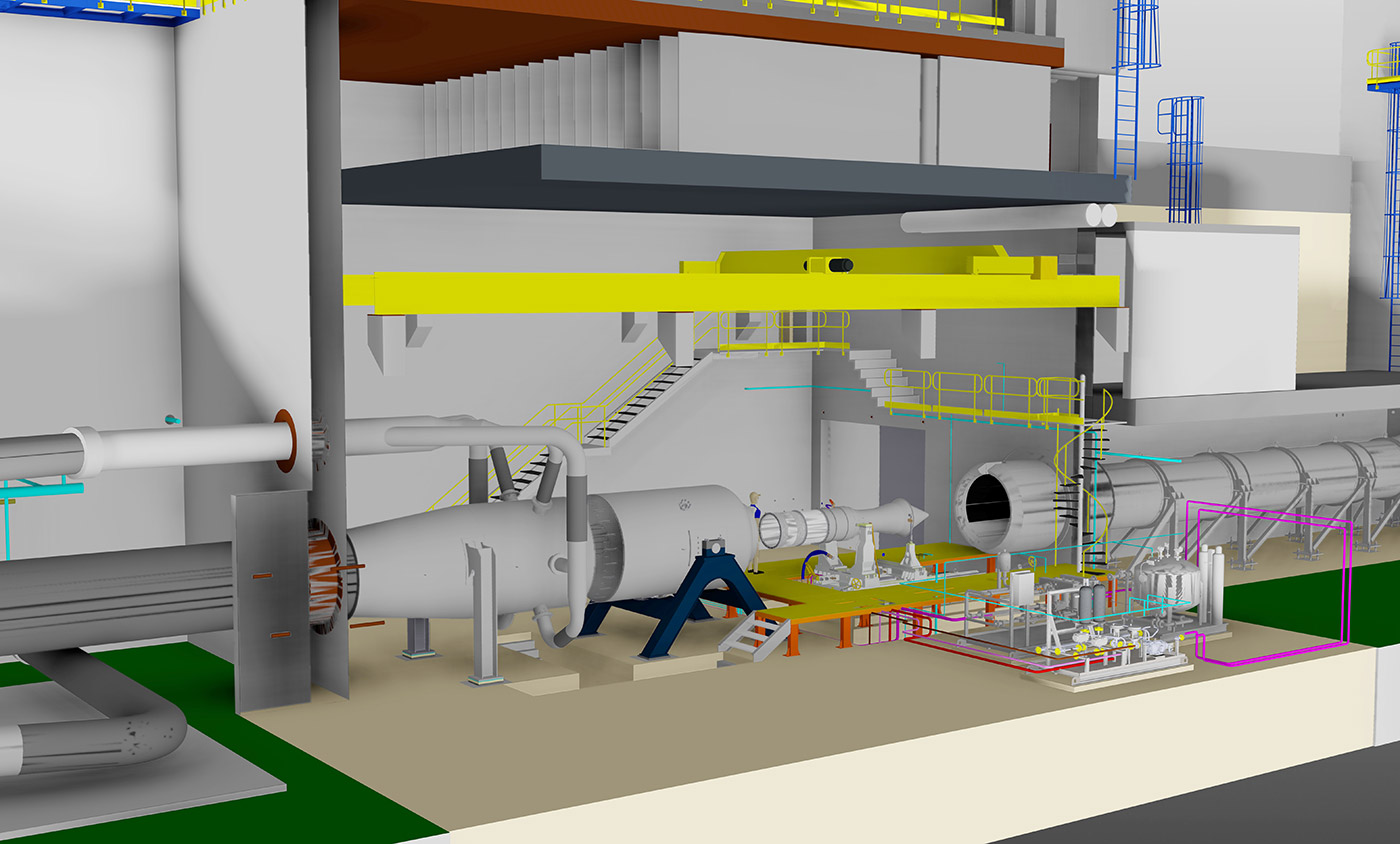

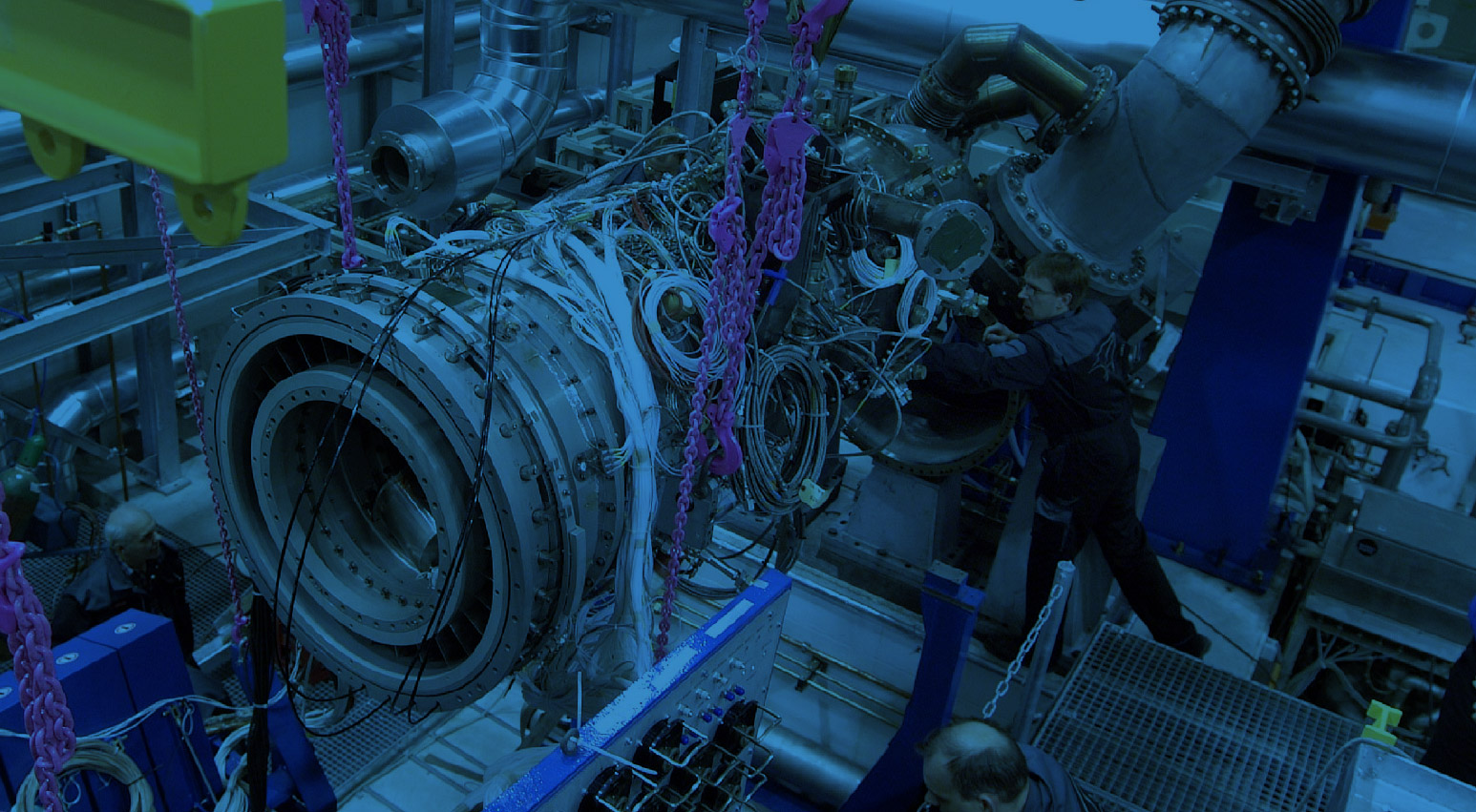

Core Engine Test Facility

MDS designs and supplies core engine test facilities to test aerodynamic performance of the aviation gas turbine engines’ core engine (gas generator) components. These facilities are equipped with pre-heated, pressurized, and/or ambient flow-conditioned inlet systems. These provide an environment for stable, repeatable, and accurate core engine test articles performance testing. The inlet system includes options for thermal boundary layer bleed system.

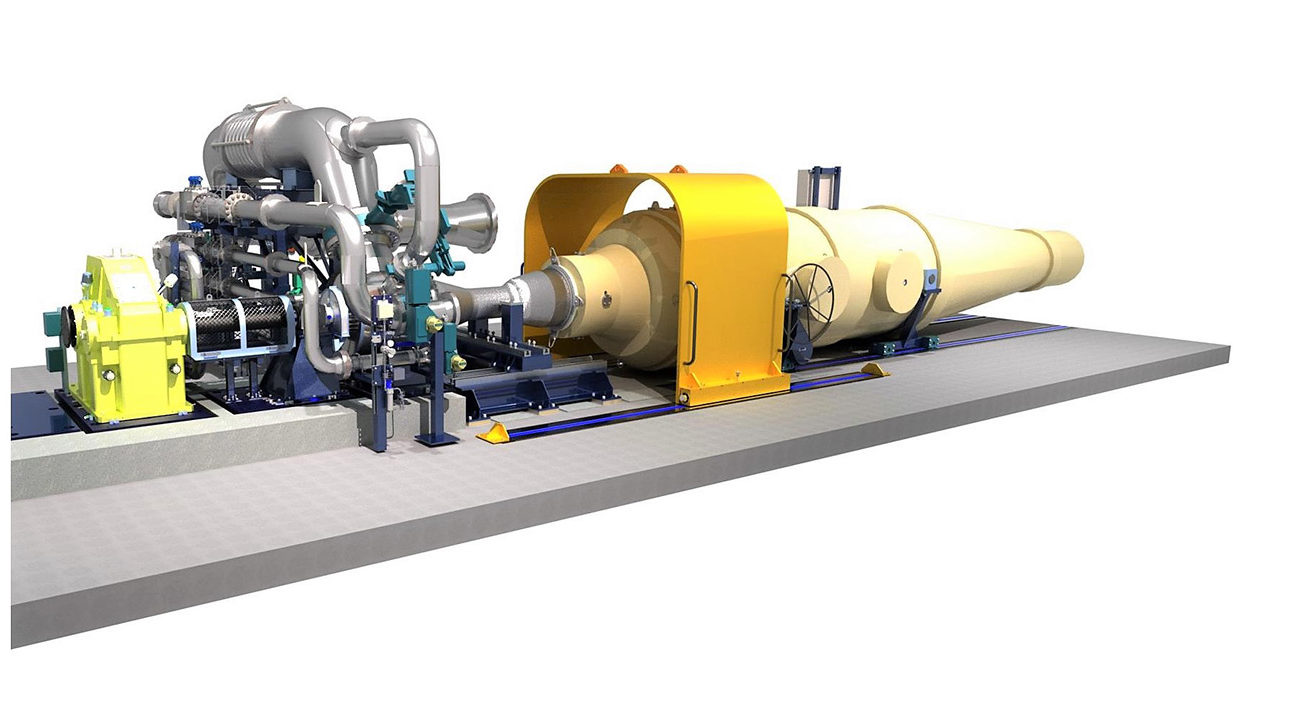

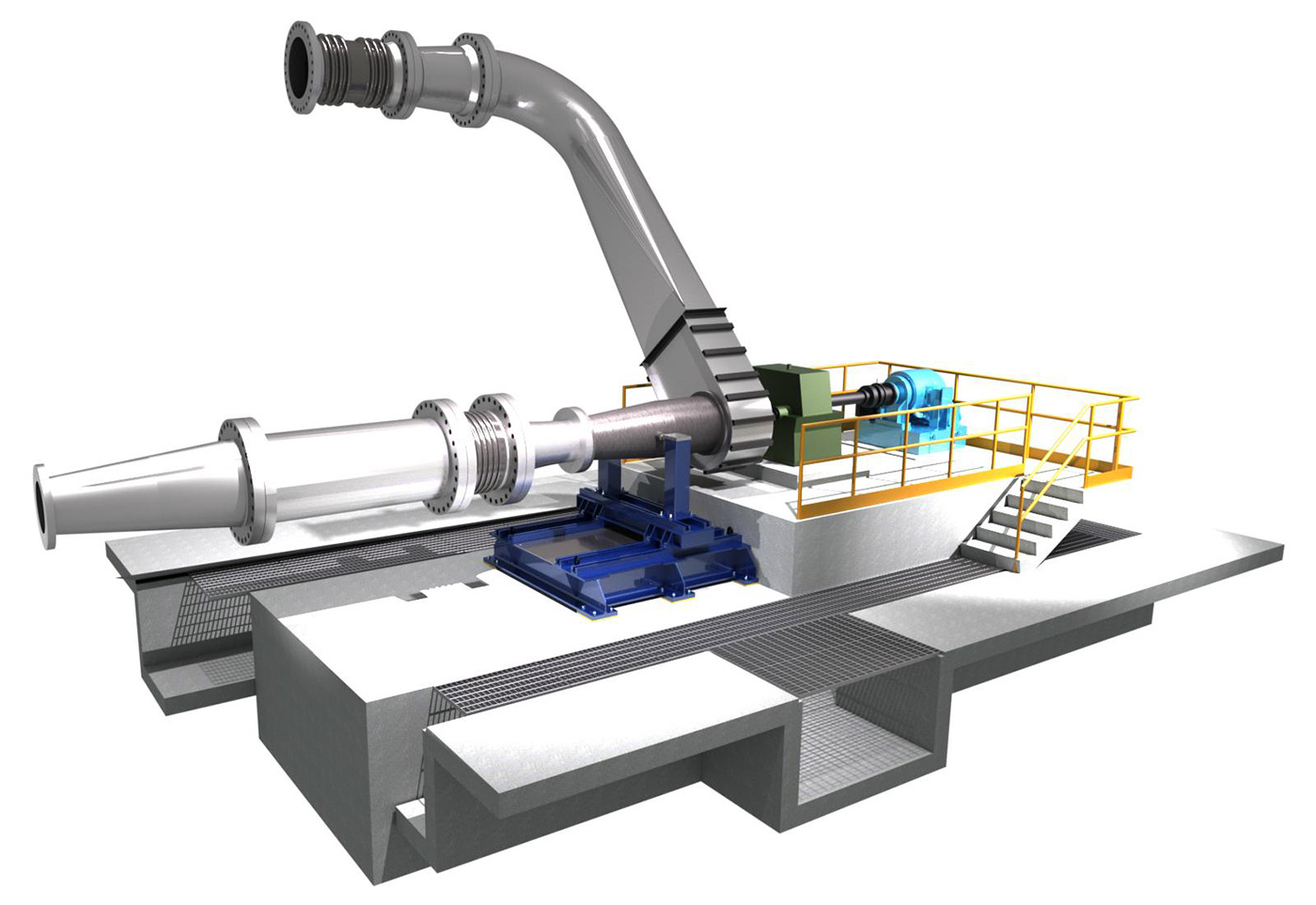

Compressor Test Facility

MDS designs and supplies compressor test facilities that provide the optimal environment for testing the development of multi-stage compressor test articles in closed-loop or open-loop configurations. The emphasis of the design is on accurate testing and on operational functionality. MDS designs allow measurement of aerodynamic/aeromechanic performance characteristics over wide range of speeds and operating lines.

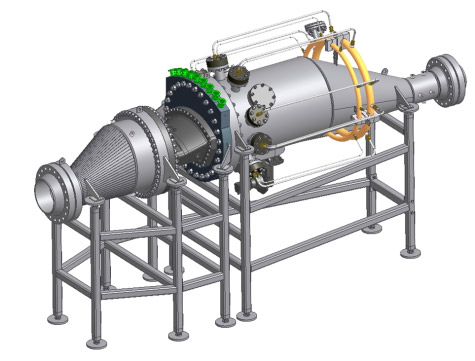

Combustion Rig

MDS designs test facilities for both aviation and industrial gas turbine engine development combustor test article applications. The MDS portfolio includes designs for pre-heated air inlet, fuel delivery, and metering. It also includes augmented exhaust test systems for a variety of combustion test articles, such as: single-nozzle combustor, multi-sector combustor, full-annular combustor, and single-can combustor. MDS designs allow for high-speed data acquisition of aerodynamic/aeromechanic performance characteristics over a wide range of combustor test article operation.

Turbine Test Facility

MDS designs and supplies turbine test facilities to accommodate complete aero-mechanical testing of gas turbine engines’ turbine system components. MDS designs include unique test system configurations that allow for testing over a wide range of inlet parameters, speeds, and operating envelopes. MDS has experience with the design of turbine test facilities for both multi-stage rotary and nozzle cascade test rigs.