We strive to provide the most rigorous testing environments to our clients, ensuring their complete confidence in the performance of their engines under extreme and unusual conditions.

Special Test Facilities & Equipment

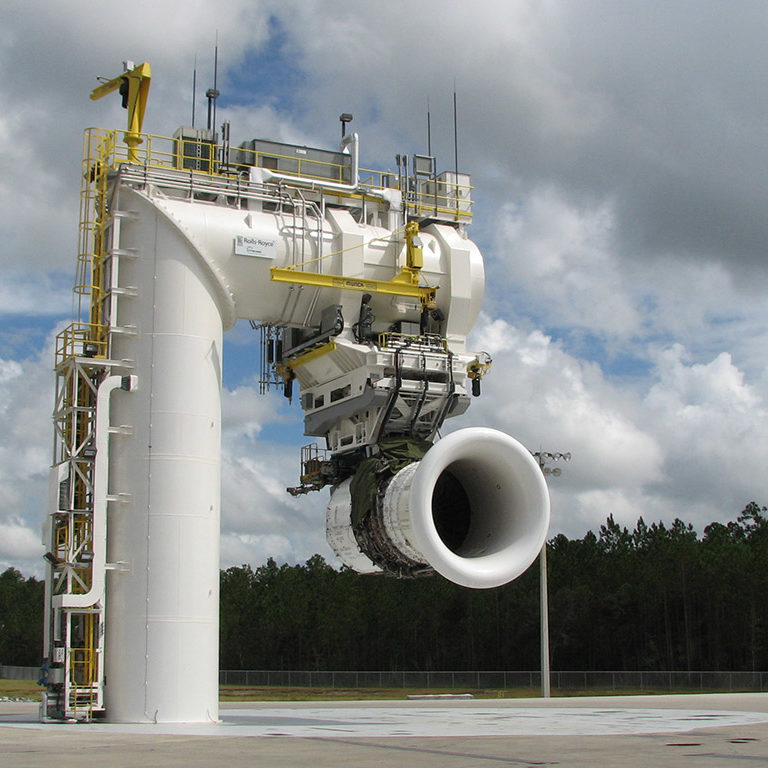

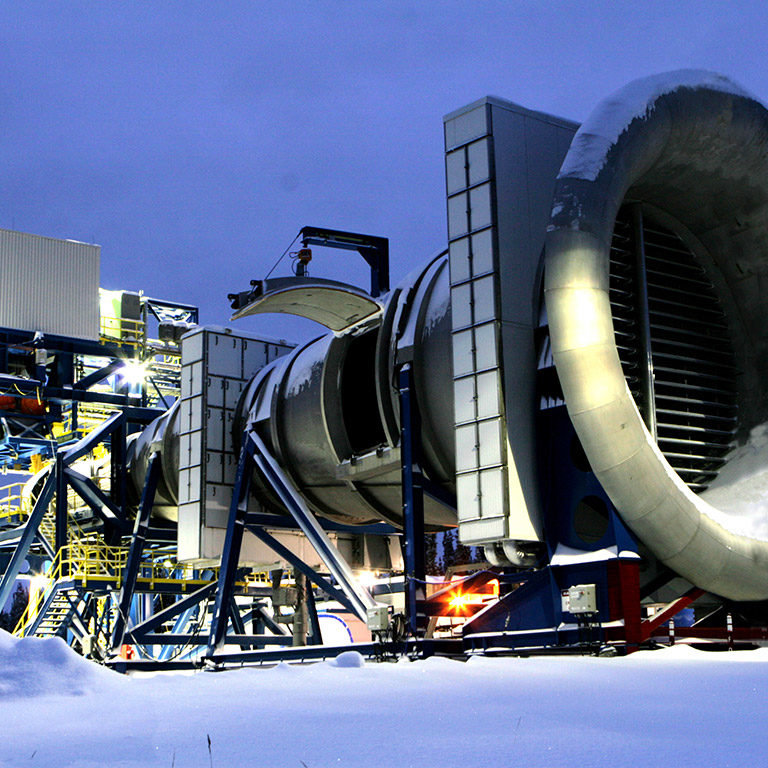

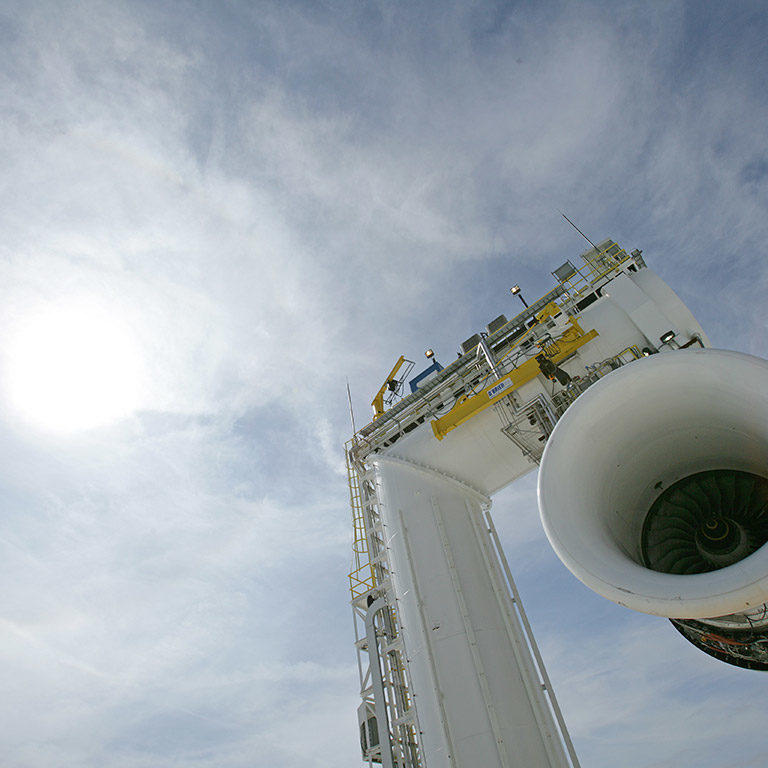

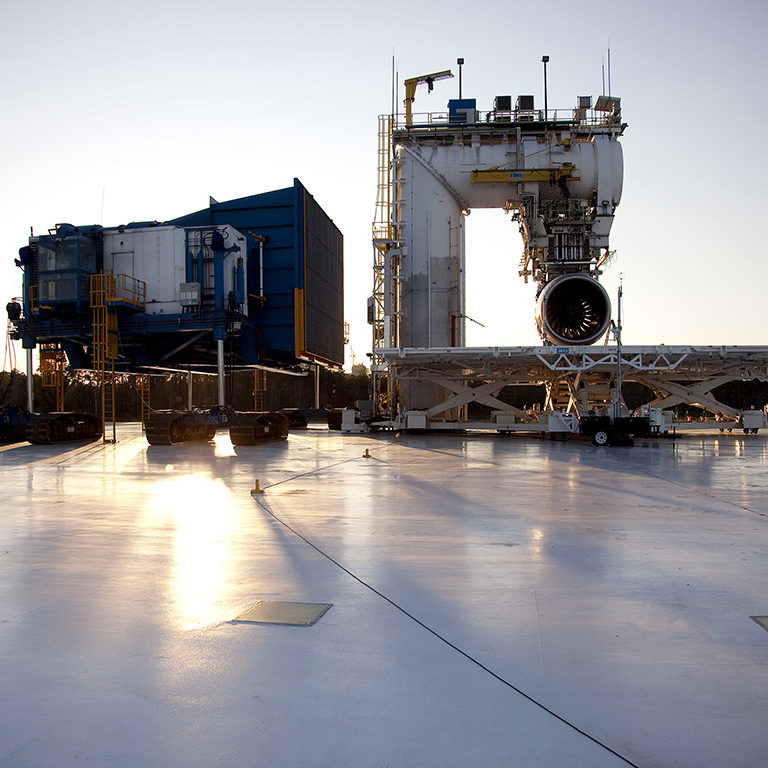

Special Test Facilities

At MDS, we understand there is no substitute for experience and knowledge when it comes to engine testing; consequently, we have built a strong foundation in special test facilities, such as outdoor testing, high altitude testing, and icing certification.

The power of technology

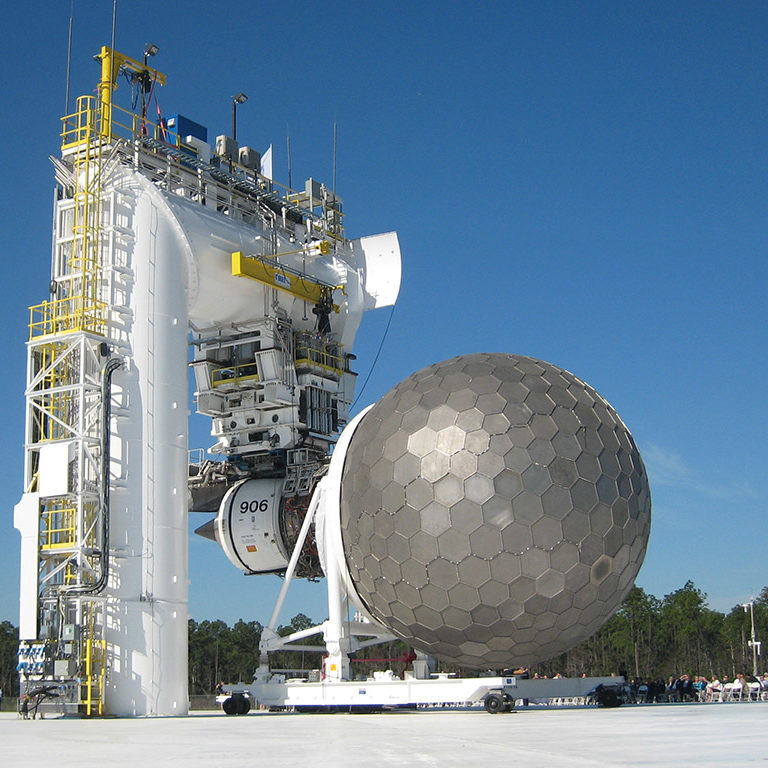

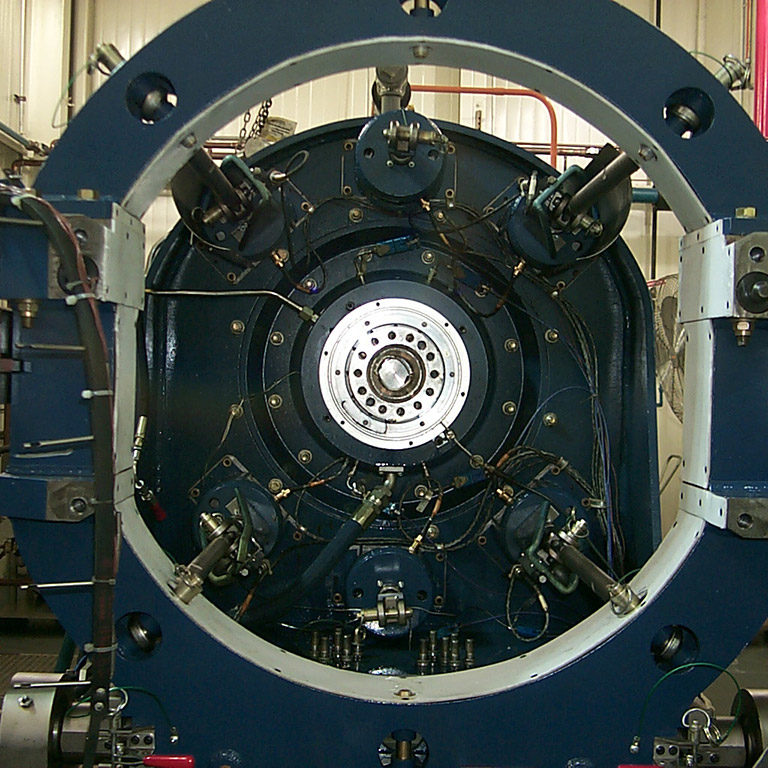

Special Purpose Test Equipment

Additionally, MDS provides an array of custom test products, services, and equipment, used as part of a state-of-the-art testing solution.

The power of precision

Our special purpose test equipment includes: 1-P Moment Rigs, Bellmouths and Airmeters, Crosswind Blowers, Ground Plane Simulation, Heated Intake Systems, Multi-Axis Thrust Measurement Systems, Re-Ingestion Screens and Anti-Vortex Mats, Starter Generator Controls and Loading Equipment, Turbulence Control Structures, and High Speed Camera and Lighting Systems.