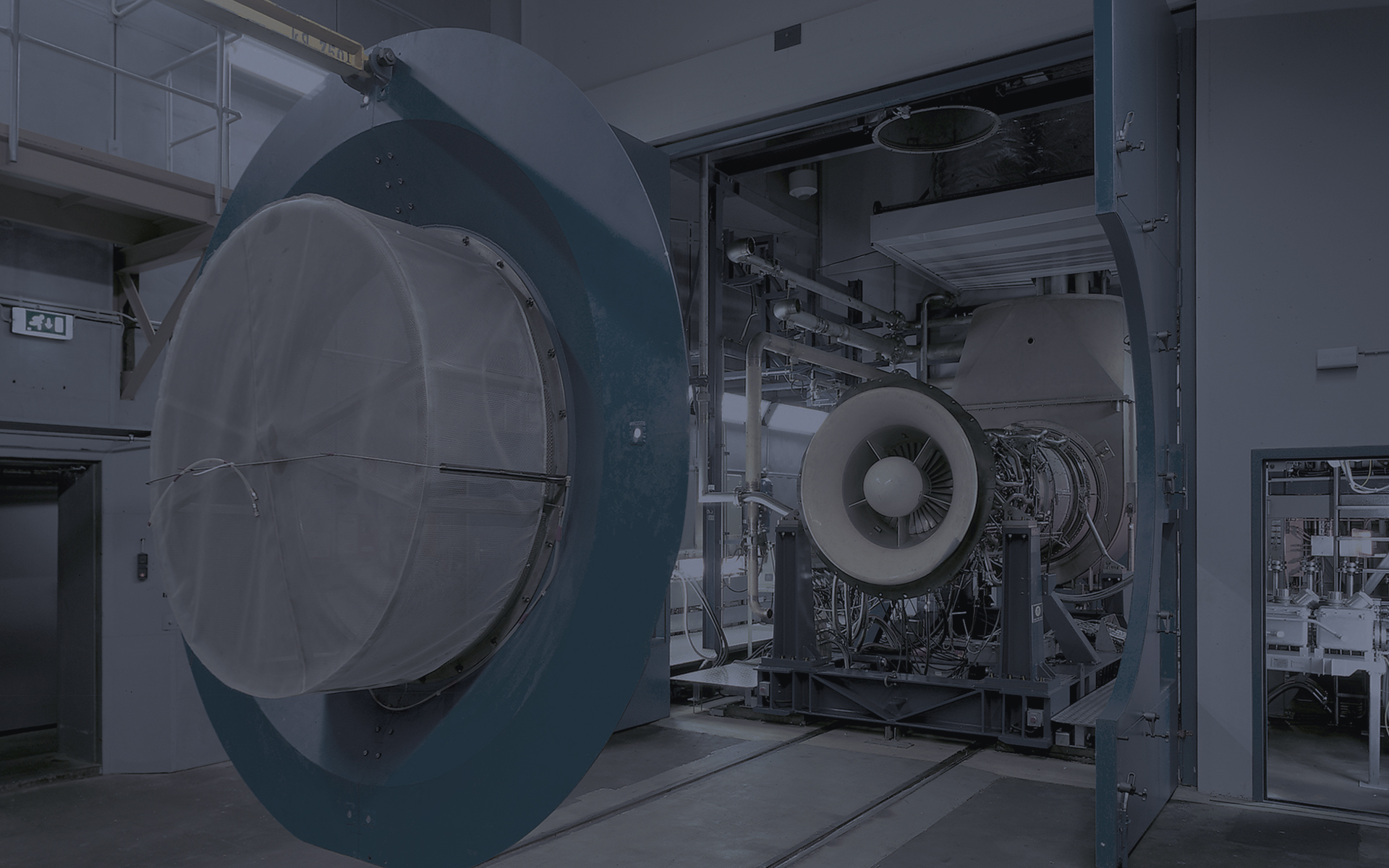

We can provide our facilities with efficient Engine Handling Systems that minimize engine installation and removal times. We can also provide quick configuration solutions to reduce engine set-up time. We can design our Engine Handling Systems to be either overhead or ground based, integrating them with the rest of the facility with a focus on operator safety while maximizing throughput and minimizing operating costs.

Engine Handling Systems

The MDS multi-direction flatbed cart is capable of moving forward, backwards, diagonally and sideways, providing ultimate flexibility for transport between engine build locations, test preparation areas, and the test cell.

The cart uses a system of cameras, in conjunction with Radio Frequency Identification (RFID), and floor markings to locate and navigate into position for equipment pick-up and docking. With the guidance system, the cart can be positioned to within 2 mm of the intended mark, and 5 mm if the user controls the cart in free mode.

MDS’ standard rail-mounted transport cart is battery powered and moves along rails that are embedded in the test cell floor. The rails terminate in between the package base frames in the test cell. The cart has an on-board drive system that delivers the Engine Package to the docking system.

Engine handling solutions include:

- Multi-directional self-propelled ground transportation systems

- Rail mounted transportation systems

- Monorail delivery systems

- Bridge cranes

- Single/dual hoist trolley assemblies

- Quick Connect hands-free adapter lifting beams

- Towable engine transportation carts

- Hydraulic and pneumatic lifting systems

- Fully adjustable engine workstations

- Engine adapter stands